1. Description of Strut Channel Roll Forming Machine

Briefly, a strut channel roll forming machine is also called Uni strut channel roll forming machine, it is used for produce the steel channels (such as supports wiring, plumbing, or mechanical components) which are usually used in air-conditioning and ventilation systems.

Actually, there are standard dimensions for common Uni struct channels, i.e. 21*41, 41*41, and 41*61, etc. Besides, there are continuous punching holes on the bottom of the channels for joints.

A roll forming equipment that manufactures strut channels is strut channel roll forming machine

2. Major Technical Parameters

No. Item Description

1 Dimension 30m x 3m x 2.5m (L*W*H)

2 Raw material Mild steel, Galvanized steel coil or strip

3 Coil Width 300 mm max

4 Thickness 1.5-2.5 mm

5 Forming stations 18 stations, gearbox transmission

6 Total power 45KW AC motor

7 Track cutting motor Track cutting motor

8 Forming speed 20m/min max

9 Roller GCr12MoV Steel, quenched, coated with hard chrome

10 Shaft 45# steel with tempering heat-treatment

11 Shaft diameter Dia 80mm

12 Roller station 18 stations

13 production speed 8-10m/min

14 Hydraulic power 5.5 KW

15 Voltage 380V/50Hz/3Ph

16 Control system PLC control system

3. Main Components of Strut Channel Roll Forming Machine

No. Item Quantity

1 Uncoiler 1 Set

2 Servo Feeder 1 Set

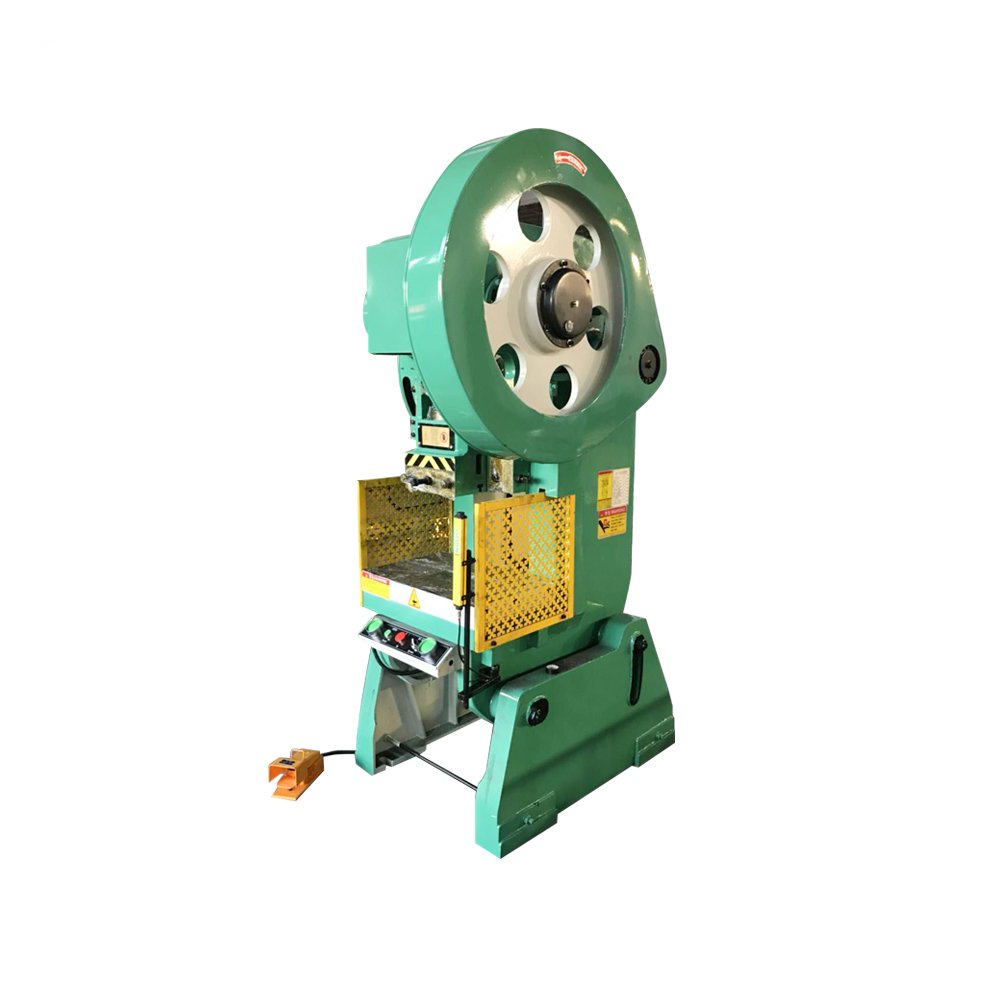

3 Hydraulic Punching Device 1 Set

4 Strut Channel Roll Former 1 Set

5 Hydraulic Cutting 1 Set

6 Hydraulic Station 1 Set

7 Ran-out Table 1 Set

8 PLC Control System Cabinet 1 Set