HBSX Sandwich Panel

Packing and Shipping

Fire damper machine catalogue

Please contact the sales people for catalogue on the right side of page

Or send mail to abby@hbsxmachinery.com

Or send whatsapp message to +86 15612977437

Sandwich Panels are composite building materials consisting of two outer layers (usually metal) and an insulating core (such as polystyrene, rock wool, or polyurethane). They are widely used in construction for walls, roofs, and partitions due to their excellent insulation, strength, and lightweight properties.

• Material: Outer layers made of galvanized steel, aluminum, or stainless steel; core materials include rock wool, polyurethane (PU), or expanded polystyrene (EPS).

• Thickness: Typically ranges from 30mm to 150mm, depending on insulation requirements.

• Applications: Used in cold storage, warehouses, industrial buildings, and residential buildings.

• Advantages: High thermal insulation, soundproofing, fire resistance, and quick installation.

Sandwich panels provide an efficient, durable, and cost-effective solution for modern construction needs.

Machines for Light Gauge Steel Framing

HBSX machines enable workers to make exact, uniform bends and cuts in sheet metal. They’re the perfect combination of machine quality and user-friendly control, with the result being extremely accurate machine tools.

Our metal folding and shearing machines are designed with you in mind, producing quality parts that fit precisely and can be assembled on the construction site as quickly as possible.

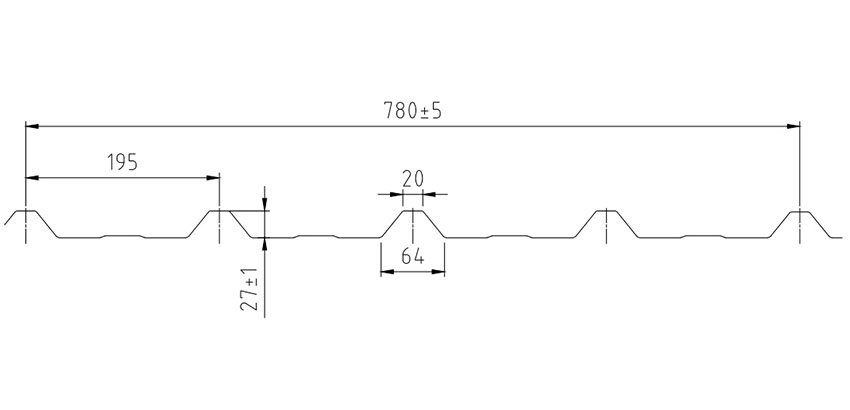

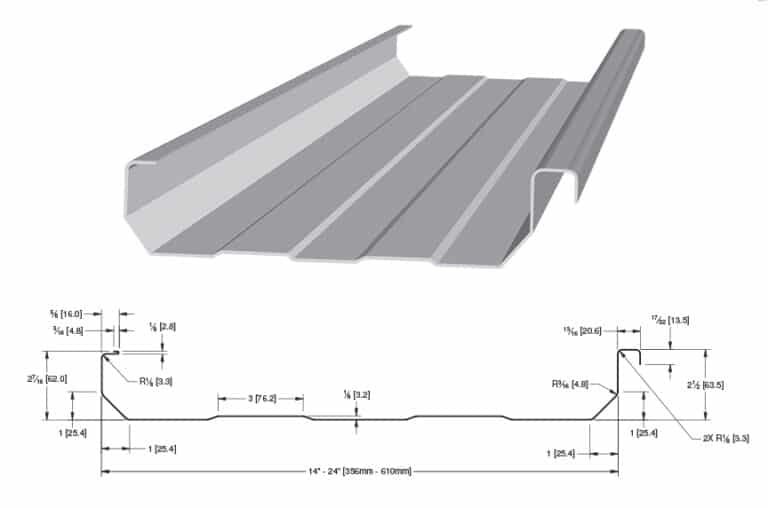

FROFILE DRAWING COLLECTION

Customers Feedback

Market is the ruler of the product, Aftersales service is the ruler of the company, time is the ruler of the quality